Your boat’s electrical system might seem mysterious, but it shouldn’t stay that way. Understanding this system empowers you to take better care of your vessel. Proper wiring keeps your electronics running smoothly, your batteries charged efficiently, and most importantly, it keeps you safe.

Whether you’re installing a new tool or troubleshooting an existing problem, grasping the things that every boater needs to know about boat wiring will help you avoid costly mistakes. Our quick guide breaks down essential components, best practices, and safety standards that apply to every boat owner.

Why Proper Boat Wiring Matters

The marine environment is harsh on electrical components. Salt spray, moisture, constant vibration, and temperature swings put stress on wiring that your car’s electrical system will never experience.

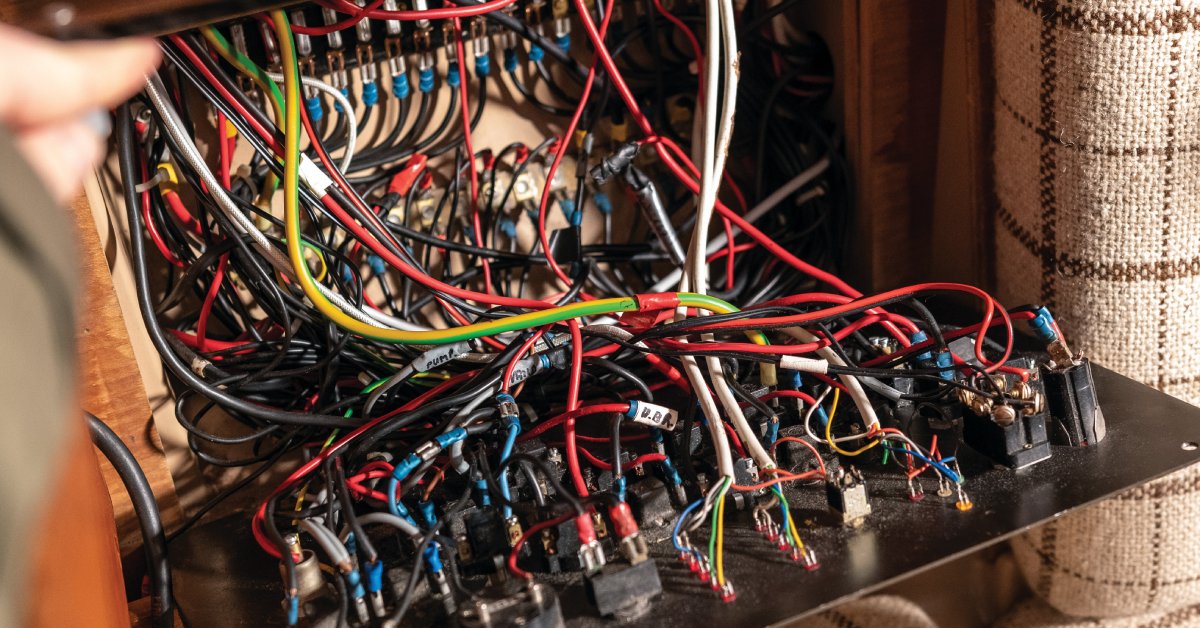

Poor connections corrode quickly in the marine environment. Undersized wire can overheat and create hazards. Using household-grade materials in a boat is asking for trouble. All of that is to say that there are plenty of wrong ways to approach the puzzle of your boat’s electrical components.

The good news is that following established standards and using marine-grade components makes wiring projects straightforward and safe.

Essential Boat Wiring Components

Marine-Grade Wire

Never use standard household wire on your boat. Marine-grade wire features tinned copper conductors that resist corrosion far better than bare copper. The stranded construction handles vibration without breaking, unlike solid wire used in homes.

Marine wiring must meet specific standards. Look for wire marked with size and type that meets UL 1426, American Boat and Yacht Council (ABYC), or US Coast Guard requirements. Quality brands like Ancor exceed these standards and provide reliable performance in the toughest conditions.

Wire gauge matters significantly. Larger gauge numbers mean smaller wire diameter. For example, a 10 AWG wire is thicker than a 14 AWG wire. Choose the right size based on the current your circuit will carry and the length of the wire run.

Fuses and Circuit Breakers

Every circuit needs proper overcurrent protection. Fuses and circuit breakers prevent wire overheating if a short circuit occurs. They’re sized to protect the wire, not necessarily the equipment.

Circuit breakers offer the convenience of resetting without replacement. Fuses are simpler and often preferred for critical circuits.

Terminals and Connectors

Quality connections matter just as much as quality wire. Marine terminals should be crimped, not just soldered. ABYC standards specifically state that solder alone cannot be the only means of mechanical connection.

Use color-coded terminals matched to your wire gauge. Red terminals fit 22-18 AWG wire, blue fits 16-14 AWG, and yellow fits 12-10 AWG. Ring terminals provide the most secure connection because they can’t pull off accidentally. Heat-shrink tubing over crimped connections protects against corrosion and accidental shorts.

Invest in a proper ratcheting crimper designed for marine terminals. A good crimp should withstand a solid pull test—15 pounds for 16 AWG connections, 40 pounds for 10 AWG.

Understanding Boat Wiring Systems

AC Systems

Some boats have 110-volt AC shore power systems for running household appliances and battery chargers. AC wiring requires different standards and expertise. These circuits must meet strict codes to prevent shock hazards.

AC wiring typically uses larger conductors bundled together. When you have a bundle of three or more current-carrying conductors, you must reduce the maximum amperage by 30-50 percent to account for heat buildup.

Unless you have specific training in marine AC systems, it’s typically best to hire a professional electrician for AC installations and repairs.

DC Systems

Most boat electronics, lights, and accessories run on 12-volt or 24-volt DC power. DC systems are more forgiving than AC, but they still require careful attention to wire sizing and connections.

DC circuits can be positive or negative switched. Most boats use negative ground systems where the negative terminal connects to the boat’s structure or a common ground point. Positive wires carry current to devices.

Color coding helps you identify circuits. Red or yellow indicates positive connections. Black indicates negative or ground. Other colors identify specific circuits like navigation lights (green) or bilge blowers (yellow with red stripe).

Connecting Power Sources

Modern lithium batteries, including the lithium trolling motor batteries from PowerHouse Lithium, have different charging requirements than traditional lead-acid batteries. Check compatibility between your battery type and charging equipment.

Battery connections demand the largest wire sizes on your boat. A starter motor might draw 300 amps briefly. Size these cables generously and keep them as short as possible.

It’s possible to wire multiple batteries in series to increase voltage (12V + 12V = 24V) or parallel to increase capacity while maintaining voltage. Series connections link positive to negative. Parallel connections link positive to positive and negative to negative.

Best Practices for Boat Wiring

Wire Sizing and Ampacity

Choosing the right wire size involves four key factors: ampacity, temperature, bundling, and voltage drop.

Ampacity refers to how much current a wire can safely carry. Each device draws a certain number of amps. Add up all devices on a circuit to determine total current requirements. Some equipment, such as windlasses, will draw much more current when starting than during normal operation.

Temperature affects ampacity. Wire in engine compartments (assumed to be 122°F) can carry 15 percent less current than wire in cooler areas. When sizing wire for hot environments, use the reduced ampacity ratings.

The ABYC recommends limiting voltage drop to 3 percent for critical circuits like electronics and navigation lights. This ensures devices receive adequate voltage to function properly. A 10 percent drop might be acceptable for non-critical circuits, but using the 3 percent standard for everything provides better reliability.

Voltage drop increases with wire length. Longer runs require larger wire to maintain acceptable voltage at the device. Wire sizing charts should account for both current and length to keep voltage drop within limits.

Preventing Corrosion

Moisture is your wiring’s worst enemy. Route wires as high above the bilge as practical. Water naturally settles in low areas where it can corrode connections.

Use adhesive-lined heat-shrink tubing over all connections. When heated, the adhesive melts and seals the connection against moisture, oil, and salt spray. This simple step dramatically extends connection life.

Apply dielectric grease to connections that might face spray or condensation. The grease displaces moisture and prevents corrosion from occurring.

Support wires every 18 inches to prevent flexing and chafing. Use cable ties or clamps designed for marine use. Route wires away from moving parts, sharp edges, and heat sources.

Protect wires passing through bulkheads with grommets. The goal is to prevent the sharp metal edges from cutting through insulation over time.

Keep Your Electrical System Reliable

Boat wiring doesn’t have to be intimidating. Using marine-grade materials, following proper sizing guidelines, making quality crimped connections, and protecting against the harsh marine environment creates electrical systems that perform reliably season after season.

What every boater needs to know about boat wiring really comes down to this: respect the marine environment, use quality components, size wiring appropriately, and make secure connections. Whether you’re adding a simple cabin light or rewiring an entire electrical panel, these fundamentals apply.

If a project feels beyond your skill level, hiring a qualified marine electrician is always the smart choice. In any case, taking time to understand your boat’s electrical system and maintaining it properly keeps you safe on the water.